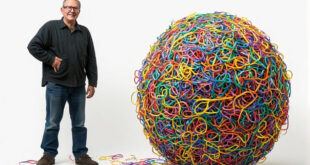

Chris Cubberley’s journey into fleet management is deeply rooted in procurement – a background that has shaped his approach to operational efficiency, supplier relationships, and strategic decision-making.

“I’ve always had a strong focus on operational efficiency and supplier collaboration through my procurement career, and that foundation has translated exceptionally well into managing fleet operations,” Cubberley explains.

He joined Mitie three and a half years ago, initially working in the procurement team, where fleet was one of his core categories. “Fleet was a significant part of my role,” he says. “So, when the opportunity arose to step into the head of fleet position in June 2024, it felt like a natural and exciting progression.”

While managing fleet teams was not new to Cubberley – he had done so previously within procurement – the chance to lead the entire fleet operation at Mitie presented a unique opportunity.

“Mitie’s commitment to sustainability and innovation made it a particularly appealing challenge. Being part of a company that is truly leading the UK’s EV transition is something I’m incredibly passionate about,” he says.

Scaling up

Since 2021, Mitie’s fleet has expanded dramatically – growing from approximately 4,700 vehicles to around 8,500 today. Of these, nearly 6,500 are electric vehicles, representing a staggering 73% of the total fleet. This makes Mitie the UK’s second-largest EV fleet, trailing only Royal Mail.

“We were early adopters in 2019, embracing EV technology at a time when options were limited,” Cubberley says. “Since then, the landscape has shifted massively. The range of electric vehicles available today is vast, and the technology has matured significantly.”

Central to Mitie’s success in the EV transition is the infrastructure investment. “We installed over 4,000 home chargers for our fleet drivers, which solved a big infrastructure challenge. It enabled our drivers to charge overnight at home, alleviating range anxiety and making EVs more practical.”

Tackling the payload challenge

While the company has achieved a near-complete transition to electric cars – around 98% – vans remain a thornier issue. “Payload and range continue to be the biggest hurdles for vans,” says Cubberley.

“Larger vehicles like 4x4s, gritters, and specialist vans carry heavy equipment and require significant payload capacity. When you electrify these vehicles, the battery weight cuts into payload, and increasing battery size reduces payload further. It’s a delicate balance.”

To address this, Mitie works closely with manufacturers, including Stellantis and Volkswagen, to influence vehicle design – pushing for improvements in range, payload, and towing capabilities tailored to their specific operational needs.

“We’re actively involved in discussions to get more from the technology and to help develop vehicles that can truly meet our business requirements,” he explains.

Small changes, big impact

Innovation isn’t always about grand gestures. Sometimes, simple, targeted changes make all the difference. Cubberley shares a great example in Mitie’s window cleaning business: “The vehicles carry heavy water tanks. We worked with the business unit to reduce the size of those tanks. That small weight saving allows electric vehicles to carry the load without compromising efficiency.”

Collaborating with business units and drivers, this practical approach helps Mitie adapt processes and rethink how work gets done in an EV context.

The fleet team also minimises vehicle weight by working with converters to reduce racking weight inside vans. “We’ve also looked at where roof racks can be eliminated because they increase drag and reduce efficiency. For instance, instead of ladders on the roof, we create storage areas inside the van,” Cubberley explains.

Every change aims to improve vehicle efficiency, helping EVs perform better in real-world conditions.

Diverse fleet, diverse needs

Mitie’s fleet supports various operations, from security and cleaning to landscaping and heavy goods transport. This diversity means that vehicles are not just about transport – they’re mobile workstations carrying specialist equipment and tools.

“Our technicians have very varied roles and requirements,” says Cubberley. “Whether it’s an HGV carrying specialist equipment or a landscape gardener’s van packed with tools, the vehicles must be fit for purpose.”

To ensure this, the fleet team engages with engineers and drivers to understand their needs and challenges. This close collaboration has helped increase EV acceptance among drivers, who have embraced the quieter, smoother, and safer experience electric vehicles offer.

“Many of our drivers have transitioned from manual diesel vehicles to EVs, and they really appreciate the difference – from heated seats and steering wheels to automatic transmissions and advanced safety features,” Cubberley says.

Training is a vital part of this transition. Mitie provides hands-on sessions, particularly when onboarding new customers or acquiring new fleets, to help drivers understand regenerative braking, vehicle tech, and EV-specific driving techniques.

Additionally, Mitie’s internal intranet hosts comprehensive resources relating to electric vehicles, ensuring ongoing education and support for drivers.

The growing importance of data

Data has become the lifeblood of Mitie’s fleet operations – a vital resource that drives every decision, strategy, and innovation. Cubberley is unequivocal about its central role:

“It’s no longer enough to simply oversee vehicles and drivers. To succeed, fleet managers must master data, harness its power, and use it to make informed, impactful decisions.”

At Mitie, data flows in from an extensive array of sources, creating a rich, multifaceted picture of fleet performance and operations.

“We pull information from everywhere: telematics devices installed in vehicles, real-time data from manufacturers, input from leasing companies, and charging patterns from both public and home chargers,” Cubberley explains. “This wealth of data allows us to understand not just what our fleet is doing, but how it’s doing it – in incredible detail.”

The value of this data is far-reaching. It guides key assessments such as determining which vehicles are suitable for electrification, based on usage patterns and operational demands.

“The insights we gain can enable us to move beyond reactive management to proactive strategy,” says Cubberley. “For example, we will be able to analyse telematics data to identify drivers who might benefit from coaching on eco-driving techniques or spot vehicles that require preventative maintenance before issues escalate.”

Looking ahead, Mitie plans to expand its telematics coverage beyond its commercial van fleet to include passenger cars over the next 12 months, further enhancing its data-driven approach.

“This integration will provide an even more complete view of our entire fleet’s performance and unlock new opportunities to improve operational efficiency,” Cubberley notes.

In an era when fleets are becoming increasingly complex and technology-rich, the ability to collect, analyse, and act on data is no longer optional – it is fundamental.

For Mitie, mastering this data is the cornerstone of its success as it continues to lead the UK’s electric vehicle transition.

Looking ahead: challenges and opportunities

Despite the progress, challenges remain – especially infrastructure. “Charging infrastructure needs to grow significantly to support an expanding EV fleet,” says Cubberley.

While home chargers solve some problems, public and workplace charging, especially for drivers without off-street parking, require local council engagement and investment.

Other hurdles include rising costs and the volatility of the second-hand EV market, which affects leasing residual values and fleet renewal strategies.

“We’re confident the market will stabilise, but it’s a real issue today,” Cubberley admits.

Alternative fuel options, such as hydrogen, are also on the horizon for Mitie’s fleet. “We recently spent a day exploring hydrogen-powered 4x4s with a manufacturer. The technology is promising, but infrastructure and market readiness still lag behind,” he says.

Heavy-duty commercial vehicles present further complexity. “Electric HGVs work well at depots with charging facilities, but on-the-road charging for these vehicles is challenging. We’re exploring all options to find eco-friendly solutions.”

Fleet manager or data scientist?

Cubberley is clear on how the role of the fleet manager will evolve.

“The next ten years, every fleet manager will need to be part data scientist. The volume of data is immense, and harnessing it to make the right decisions is critical.”

AI and advanced analytics will play a central role in this transformation, providing real-time insights on trip patterns, vehicle compatibility, fleet optimization, and maintenance needs.

“At Mitie, we’ve started exploring AI-powered tools with our leasing partners. For example, automated inspection checks and AI-driven incident reporting can speed up repairs and reduce downtime,” Cubberley says.

“Predictive maintenance enabled by AI could allow us to preempt breakdowns, order parts early, and keep vehicles on the road longer – reducing hire costs and increasing engineer productivity.”

Cubberley believes AI will streamline fleet management, enhance driver experience, and facilitate cooperation with manufacturers and leasing companies but acknowledges this as the start of the journey.

A personal commitment to sustainability

For Cubberley and Mitie, sustainability is not just a corporate goal – it’s a personal and operational imperative.

“We have a diverse policy, but everything we do is about figuring out how to make EVs work in each business area,” he says.

“It’s not always possible, but in nine out of ten cases, it can be done.”

This commitment has driven the company to exceed its 2024 target of 85% electric vehicles, excluding specialist vehicles that cannot yet be electrified.

“We’ll continue pushing manufacturers and exploring technology to electrify that remaining 15%,” Cubberley affirms.

Cubberley himself drives a company car and finds the electric experience transformative.

“I can’t imagine going back to petrol or diesel now. Charging overnight and not worrying about petrol stations has become second nature.

“The quietness and smoothness of the drive are just amazing.”

This sentiment reflects wider driver feedback – a key factor in the successful EV transition of the fleet.

With a clear executive directive, Mitie is proving that with the right blend of innovation, data mastery, and collaboration, the transition to a low-carbon, efficient fleet is achievable and significantly underway.

“The challenges ahead are real, but so are the opportunities,” Cubberley reflects. “By embracing new technologies, listening to our drivers, and pushing the boundaries of what’s possible, we’re not just adapting to the future of mobility – we’re actively shaping it.”

In a world where every mile counts toward a greener tomorrow, Mitie’s fleet stands as a powerful example of how forward-thinking leadership and data-driven strategies can accelerate change – one electric vehicle, one innovation, and one decision at a time.

Source link